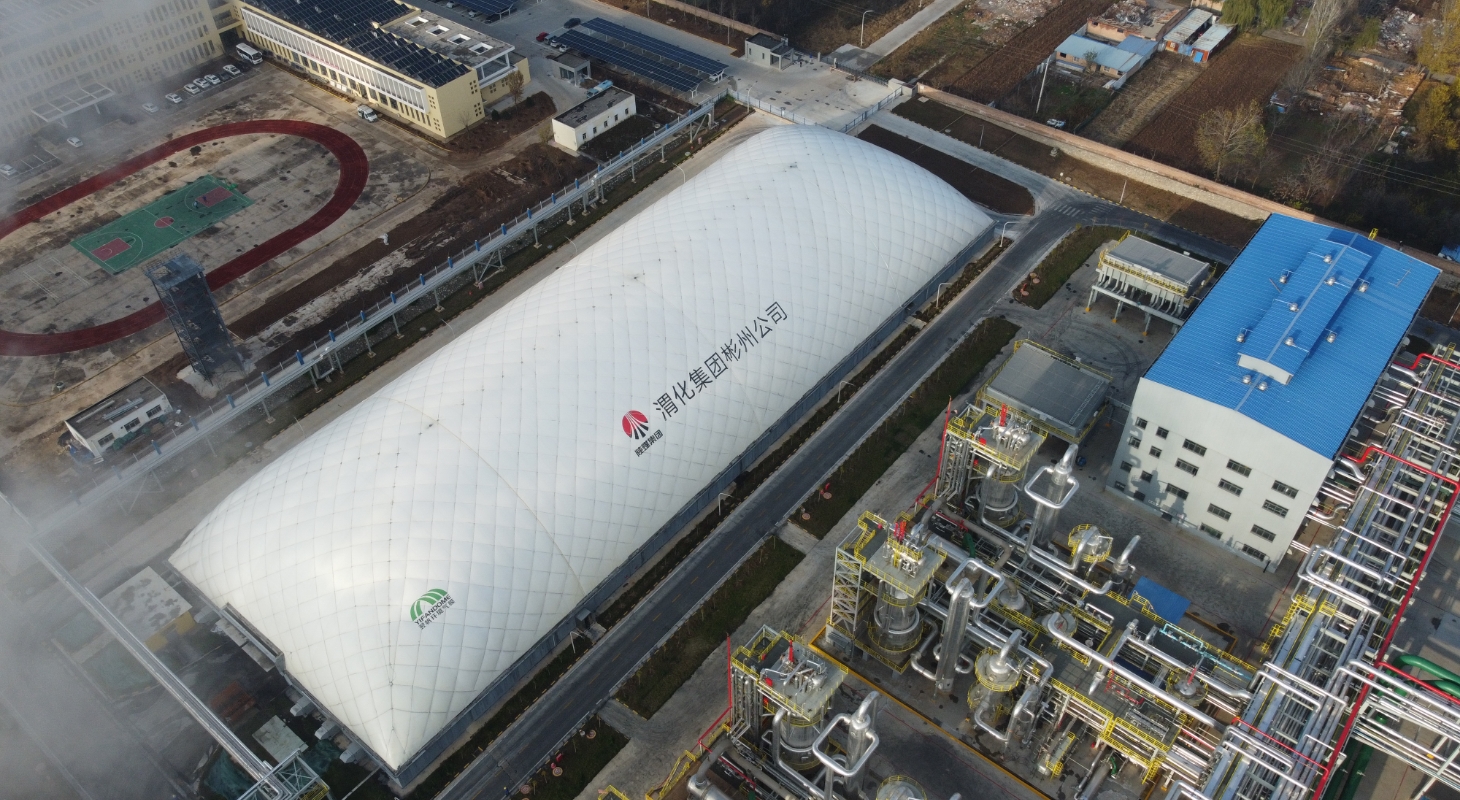

The processing of gas film materials is a key process for constructing lightweight building structures through precision technology, with high-strength PVDF film materials as the core. The core steps include: ① material selection and pretreatment, selecting PVDF membrane materials that are corrosion-resistant and UV resistant, and conducting tensile strength testing to ensure that the performance meets the standards; ② Automated cutting, precise cutting based on CAD drawings, polishing edges to ensure smooth seams; ③ High frequency heat sealing, precisely controlled by temperature (120-150 ℃) and pressure (0.4-0.6MPa), seamlessly bonds the membrane to form an airtight structure; ④ Quality inspection, with a focus on verifying coating uniformity, joint tensile strength (≥ 30MPa), and weather resistance. During processing, wrinkles and thermal damage should be avoided, and intelligent winding technology should be used to prevent deformation. The finished product is widely used in large-span spaces such as grain warehouses and sports venues, combining the advantages of lightweight (1/10 of the weight of traditional building materials), high strength and durability (with a lifespan of over 25 years), and fast construction, highlighting the modern engineering characteristics of high efficiency and environmental protection.

Online consult

Online consult

Telephone

Telephone

Cooperation

Cooperation

Back to Top

Back to Top