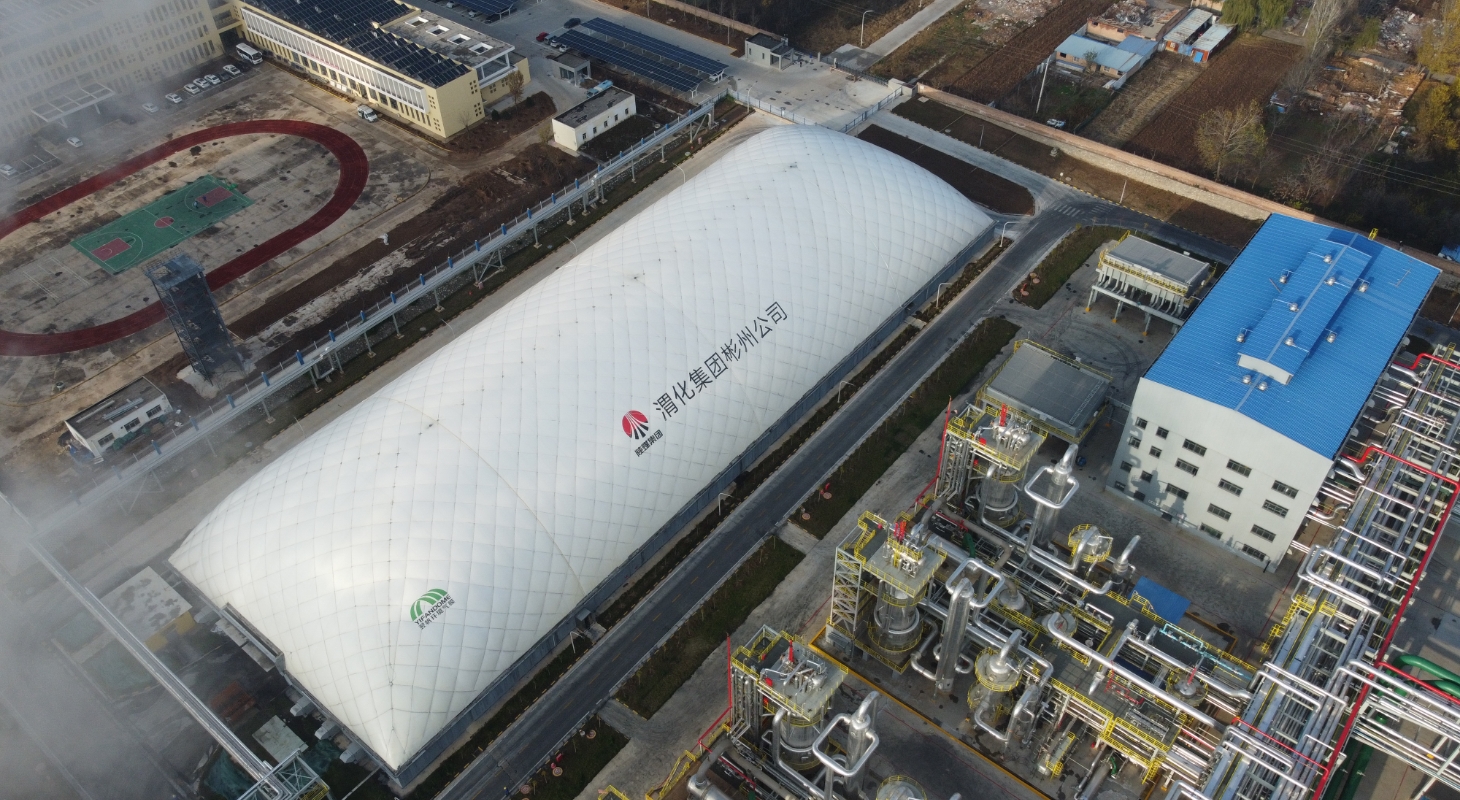

Gas film technology is widely used in the industrial field due to its fast construction, large-span column free space, and environmental protection characteristics

Storage and logistics: used for storing bulk materials such as grain, coal, and mineral powder. The air film warehouse is dust-proof and moisture-proof (humidity control ± 5%), with wind pressure resistance ≥ 0.6kPa, reducing losses by more than 15%;

Environmentally friendly closure: covering sewage treatment tanks and landfill sites, blocking odor volatilization (reducing VOCs emissions by 90%), and supporting intelligent ventilation systems to achieve gas emission standards;

Production workshop: Build a lightweight factory building with a span of up to 200 meters, no supporting columns inside, suitable for heavy equipment layout, and use transparent film materials (light transmittance of 30%~70%) to reduce lighting energy consumption;

Energy sector: LNG gas film storage tanks are resistant to low temperatures (-160 ℃), leak proof, and ensure safe energy storage.

The air film adopts PVDF/PVC high-strength membrane material (tensile strength ≥ 40MPa) with a lifespan of over 25 years. Combined with IoT monitoring (deformation error ± 2cm) and rapid inflation technology (built within 24 hours), it combines economy and sustainability to promote green upgrading of industrial facilities.

Online consult

Online consult

Telephone

Telephone

Cooperation

Cooperation

Back to Top

Back to Top