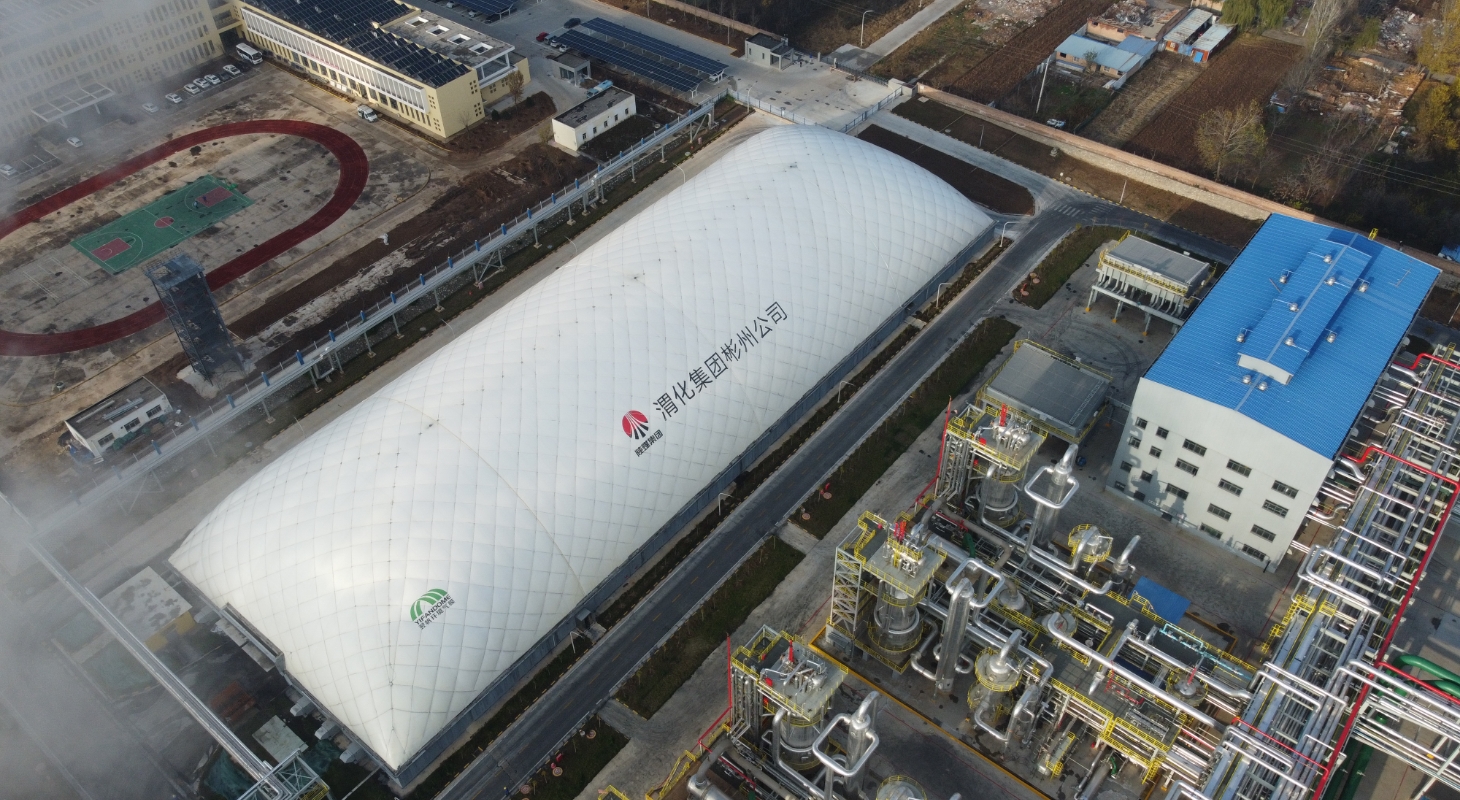

The research and development of membrane equipment focuses on intelligence, high precision, and stability, covering core aspects such as inflation systems, heat sealing machinery, intelligent control, and detection devices. The key technologies include: ① Intelligent inflation unit, integrating variable frequency fan and pressure sensor to achieve constant pressure gas supply (± 50Pa error); ② High frequency heat sealing machine, using PID temperature control (accuracy ± 1 ℃) and pressure feedback to ensure joint strength ≥ 30MPa; ③ Automated cutting line, based on 3D laser scanning and CAD linkage, with cutting accuracy of ± 0.5mm; ④ Real time monitoring system that monitors membrane stress, deformation, and environmental data through IoT technology. In research and development, breakthroughs are needed in material compatibility (such as PVDF/PVC adaptation), energy optimization (energy saving of over 30%), and modular design to meet the rapid construction needs of scenarios such as grain silos and venues. The future direction includes AI driven fault prediction, lightweight mobile devices, and green manufacturing processes, promoting the efficient and large-scale application of gas film buildings.

Online consult

Online consult

Telephone

Telephone

Cooperation

Cooperation

Back to Top

Back to Top