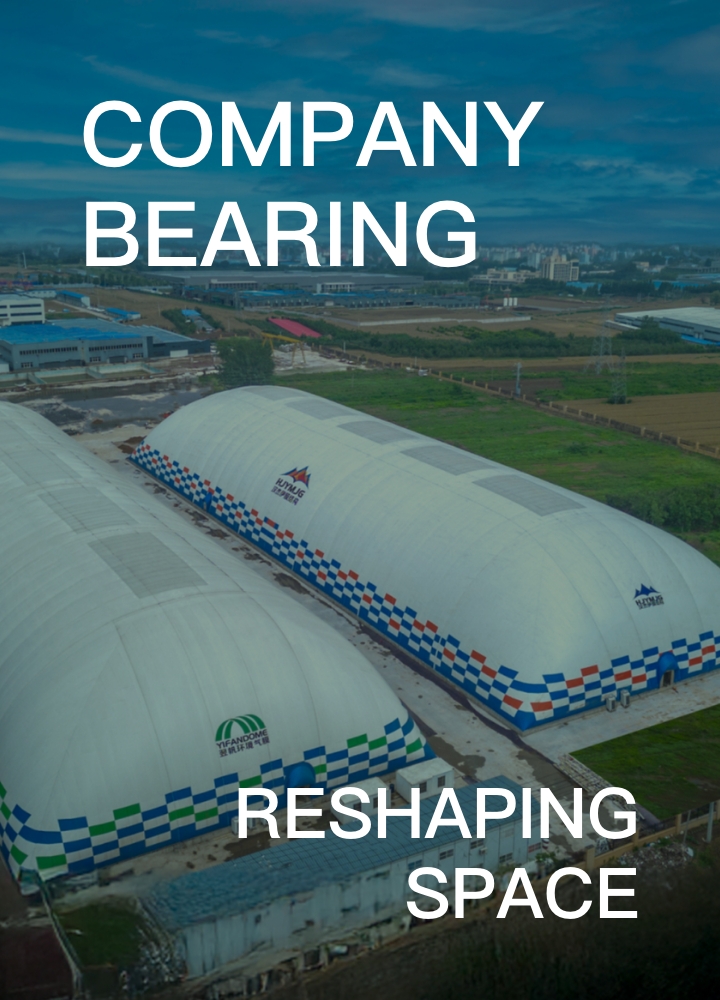

The company operates a production and R&D base spanning over 40,000 square meters, including a specialized membrane material processing workshop of 20,000 square meters and a steel component fabrication workshop of 10,000 square meters. With an annual membrane material processing capacity of 2 million square meters and the ability to produce 3,000 tons of steel components per year, the facility is equipped with advanced machinery such as CNC pipe profiling machines, dedicated steel tube shot blasting machines, plasma plate cutting machines, and high-power pipe bending machines.

Key membrane structure accessories, including anchors and locks, are independently developed, designed, and manufactured by the company, ensuring unparalleled advantages in product compatibility and system integration. This vertical integration enables seamless alignment between design specifications and production outcomes, reinforcing the company’s technical leadership in the membrane structure industry.